Imaging technology is at the heart of Industry 5.0, where human-machine collaboration is the cornerstone.

The Transition from Industry 4.0 to Industry 5.0

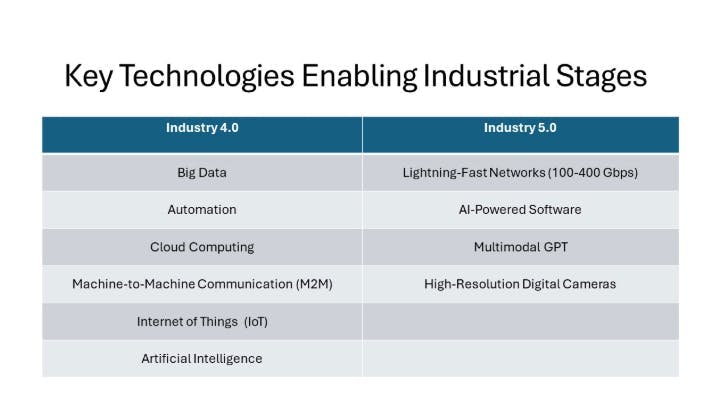

Industry 5.0, also known as 5IR, represents the next step in manufacturing's evolution. Unlike its predecessor, Industry 4.0, which brought groundbreaking advancements like big data, automation, cloud computing, AI, and IoT, 5IR doesn't seek to revolutionize but rather to enhance and humanize these technologies.

While many businesses are still adapting to Industry 4.0, some have already begun embracing 5IR's principles. The primary goal is to foster deeper human-machine cooperation. By leveraging Industry 4.0 technologies, companies can blend automated efficiency with human creativity. This combination promises a competitive edge and a more agile approach to problem-solving.

Human-Centric Impact of Industry 5.0

Industry 5.0 places humans back at the center of industrial processes. In this new era, workers are not just passive observers but active participants in decision-making. This involvement allows automated processes, often rigid and inflexible, to become more adaptive and responsive.

Key Applications of Industry 5.0

Manufacturing Industry 5.0 will see a surge in the use of AI-driven collaborative robots (Cobots) and intelligent devices. These advanced cobots can observe and learn complex human tasks, similar to apprentices. This capability frees workers from monotonous duties, enabling them to focus on creativity and customer value. Smart devices, equipped with specialized algorithms, can visually interpret and analyze inputs, making them capable of detecting subtle differences that human eyes might miss.

Agriculture The potential of 5IR in agriculture is immense. AI can identify plant diseases and boost crop yields, while autonomous drones and machinery, like tractors and harvesters, can revolutionize productivity.

Security AI, by analyzing video footage, can detect patterns in human behavior, allowing for early identification of potential security threats. Additionally, retail security footage, combined with data analytics, can offer valuable insights into consumer behavior and preferences.

Healthcare Industry 5.0 in healthcare will merge human expertise with advanced technology, enhancing diagnostics, treatments, and drug development. AI-powered medical imaging, for example, supports personalized care and aids doctors in decision-making.

Transportation Integrating visual systems in vehicles and infrastructure can streamline logistics, reduce traffic, and promote sustainability. This integration not only benefits businesses but also enhances safety and environmental responsibility.

The Role of Machine Vision in Industry 5.0

These examples underscore how crucial imaging technology is for realizing 5IR's ambitions. In the 5IR era, robots, cobots, and other machines gain both AI-driven "insight" and human-like "vision" through advanced machine vision.

From Camera to PC: The Power of Frame Grabbers

Despite their different focuses, Industry 4.0 and 5.0 share a reliance on the real-time transmission of visual data. In 5IR, a key component is the frame grabber, which bridges the camera and the PC. This device captures images and transfers them to the PC's memory for processing.

Frame grabbers support various transmission standards, such as CoaXPress (CXP), Camera Link (CL), and LVDS. Compared to methods like GigE Vision or USB3, CoaXPress frame grabbers offer faster and more reliable data transmission. The CXP 2.1 interface, in particular, is well-suited for 5IR's imaging needs, with transfer speeds of up to 50 Gbps using four cables.

CoaXPress Over Fiber: The Future of Data Transmission

The latest advancement in this area is CoaXPress Over Fiber (CoF). Industry experts believe CoF will enable speeds of up to 400 Gbps, far exceeding coaxial cables' capabilities. CoF can operate over long distances without needing extenders, making it ideal for large-scale industrial applications.

AI and CoaXPress: A Winning Combination

AI-powered technologies, particularly those leveraging GPUs, are essential for enhancing productivity and competitiveness. GPUs, with their parallel processing power, are driving deep learning and high-performance computing. CoaXPress frame grabbers are increasingly optimized to work with the latest GPUs, enabling faster deployment of vision systems and AI applications.

My Take on Industry 5.0 and Machine Vision

As an industrial automation engineer, I see Industry 5.0 as a transformative force. The integration of machine vision and AI with human creativity is not just a technological advance but a shift towards a more human-centric industrial landscape. The seamless interaction between humans and machines will lead to smarter, more efficient processes that still value human input and ingenuity.

Machine vision will be pivotal in this transition. With the continuous evolution of technologies like CoaXPress, we're not just improving systems but also creating environments where human and machine collaboration thrives. This blend of speed, precision, and human touch is what will make Industry 5.0 truly revolutionary.